White Aluminum Oxide

67.0 INR/Kilograms

Product Details:

- Metal Type Non-metallic

- Usage & Applications Sandblasting, Surface preparation, Polishing, Refractory material, Abrasive tools, Lapping, Ceramic and electronic industries

- Grade Industrial Grade

- Purity(%) 99.5% minimum

- Melting Point 2050C

- Boiling point 2980C

- Particle Size F8-F220, Custom sizes available

- Click to View more

X

White Aluminum Oxide Price And Quantity

- 100 Kilograms

- 67.0 INR/Kilograms

White Aluminum Oxide Product Specifications

- 99.5% minimum

- Metal Powder

- 2050C

- Non-metallic

- 1 Year

- Sandblasting, Surface preparation, Polishing, Refractory material, Abrasive tools, Lapping, Ceramic and electronic industries

- Al2O3 99.5%

- Industrial Grade

- F8-F220, Custom sizes available

- Customizable as per requirement

- Powder

- WHITE

- 4.00 Gram per cubic centimeter(g/cm3)

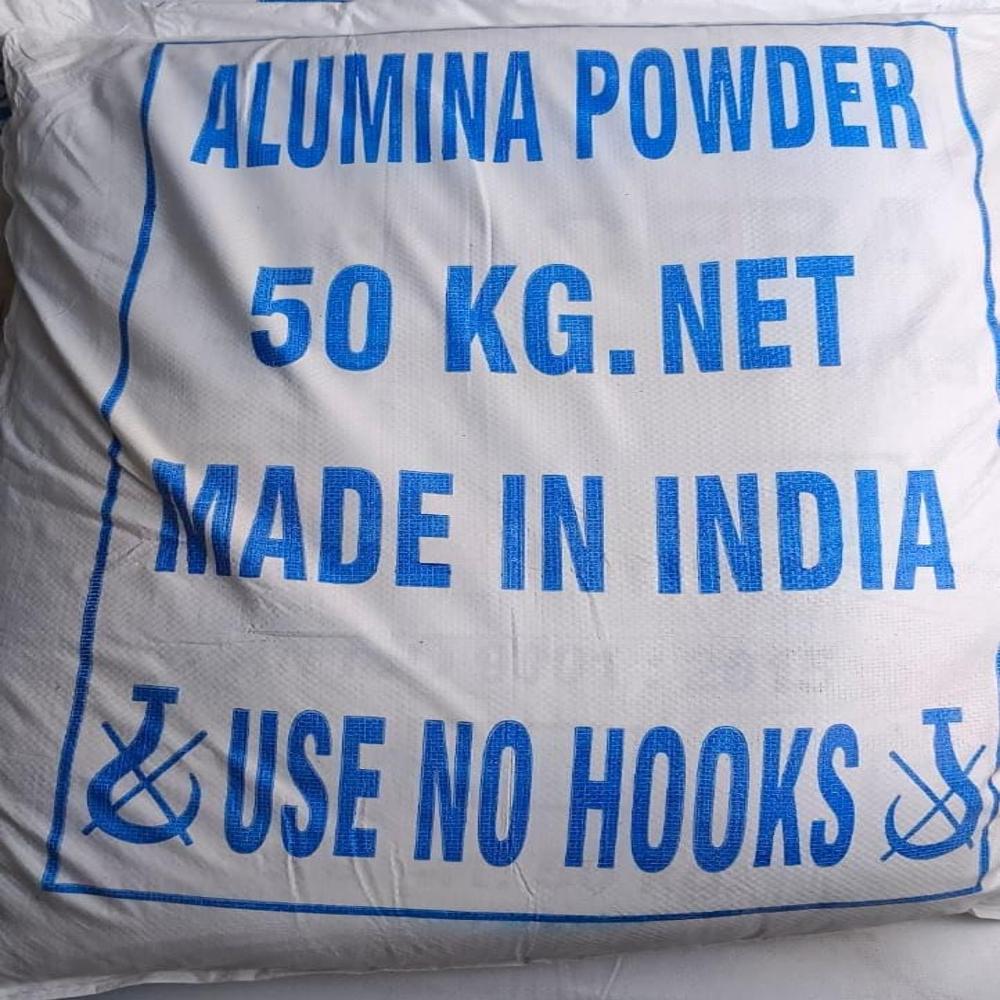

- 25 kg / 50 kg bags or as required

- Custom dimensions possible

- 2980C

- Aluminum

White Aluminum Oxide Trade Information

- 2-3 Days

- HDPE BAG

- All India

Product Description

White aluminum oxide is a type of abrasive material known for its high purity and hardness. It is produced by the fusion of high-quality aluminum oxide in an electric arc furnace. The resulting crystal structure gives white aluminum oxide its unique characteristics, making it suitable for various abrasive applications. It is commonly used in industries such as metal fabrication, automotive, aerospace, and electronics for tasks like surface preparation, polishing, and finishing.

Frequently Asked Questions (FAQ):

Q: What is white aluminum oxide?

A: White aluminum oxide is an abrasive material derived from high-quality aluminum oxide. It is produced through a process called fusion, where aluminum oxide is melted in an electric arc furnace and then cooled and crushed into fine particles. The resulting white aluminum oxide crystals possess high purity, hardness, and strength, making it a valuable abrasive material for numerous applications.

Q: What are the properties of white aluminum oxide?

A: White aluminum oxide is characterized by its white color, high purity, and exceptional hardness. It has a Mohs hardness rating of 9, making it one of the hardest abrasive materials available. It is also chemically stable and resistant to heat. These properties make white aluminum oxide ideal for tasks that require aggressive cutting, grinding, or polishing, especially on hard surfaces or materials.

Q: What are the common uses of white aluminum oxide?

A: White aluminum oxide finds applications in various industries. It is commonly used for surface preparation, cleaning, and finishing tasks in metal fabrication, automotive refinishing, aerospace, and electronics. It is employed in processes like grinding, polishing, sandblasting, and honing to remove rust, corrosion, paint, or scale from metal surfaces. White aluminum oxide is also utilized in the production of precision tools, ceramic products, and refractory materials.

Q: How is white aluminum oxide different from other abrasive materials?

A: White aluminum oxide stands out from other abrasive materials due to its high purity and hardness. Compared to other types of aluminum oxide abrasives, white aluminum oxide has a higher percentage of aluminum oxide and fewer impurities. Its hardness and cutting ability make it well-suited for tasks that require precision, control, and a fine finish. Additionally, white aluminum oxide generates less heat during use, reducing the risk of heat-related damage to the workpiece.

Exceptional Performance for Industrial Applications

White Aluminum Oxide stands out with its impressive hardness and purity, making it ideal for demanding tasks such as sandblasting, surface preparation, and abrasive lapping. Its low magnetic content and high refractive index ensure compatibility with various technical applications while minimizing interference in sensitive operations.

Customizable and Reliable Material Solutions

Offered in a range of particle sizes from F8 to F220 and supplied in bulk or customized packaging, this product is tailored to meet unique industry specifications. Its refractory capabilities and chemical stability make it indispensable in ceramics and electronic manufacturing, promising consistent quality and long-term reliability.

FAQs of White Aluminum Oxide:

Q: How is White Aluminum Oxide typically used in industrial applications?

A: White Aluminum Oxide is employed in processes such as sandblasting, polishing, surface preparation, manufacturing of abrasive tools, lapping, and as a refractory material. Its high hardness and purity ensure effective material removal and surface finishing in manufacturing and electronic industries.Q: What benefits does White Aluminum Oxide offer over other abrasives?

A: This material boasts a Mohs hardness of 9, exceptional purity (minimum 99.5% Al2O3), and is free from magnetic contaminants. It is also non-toxic, chemically stable, and insoluble in water, providing enhanced cutting efficiency, consistent results, and environmental safety.Q: When should I choose custom particle sizes or dimensions for my application?

A: Custom particle size or dimensions are recommended when your process demands specific abrasive performance, unique surface textures, or compatibility with specialized equipment. Customization is available from F8 to F220 to meet different industrial needs.Q: Where can I source White Aluminum Oxide, and in what quantities is it available?

A: White Aluminum Oxide can be sourced directly from manufacturers, exporters, suppliers, and wholesalers based in India. It is typically available in 25 kg or 50 kg bags, with the option for custom packaging to suit bulk requirements.Q: What is the process for using White Aluminum Oxide in sandblasting?

A: The typical process involves selecting the appropriate particle size based on the surface finish needed, loading the abrasive into sandblasting equipment, and applying it to the substrate. Its high density and hardness ensure efficient removal of contaminants and surface preparation.Q: Is White Aluminum Oxide safe to handle and use?

A: Yes, White Aluminum Oxide is non-toxic and has a low magnetic material content ( 0.003%). It is inorganic and does not have an ignition point, ensuring safety during handling and operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS