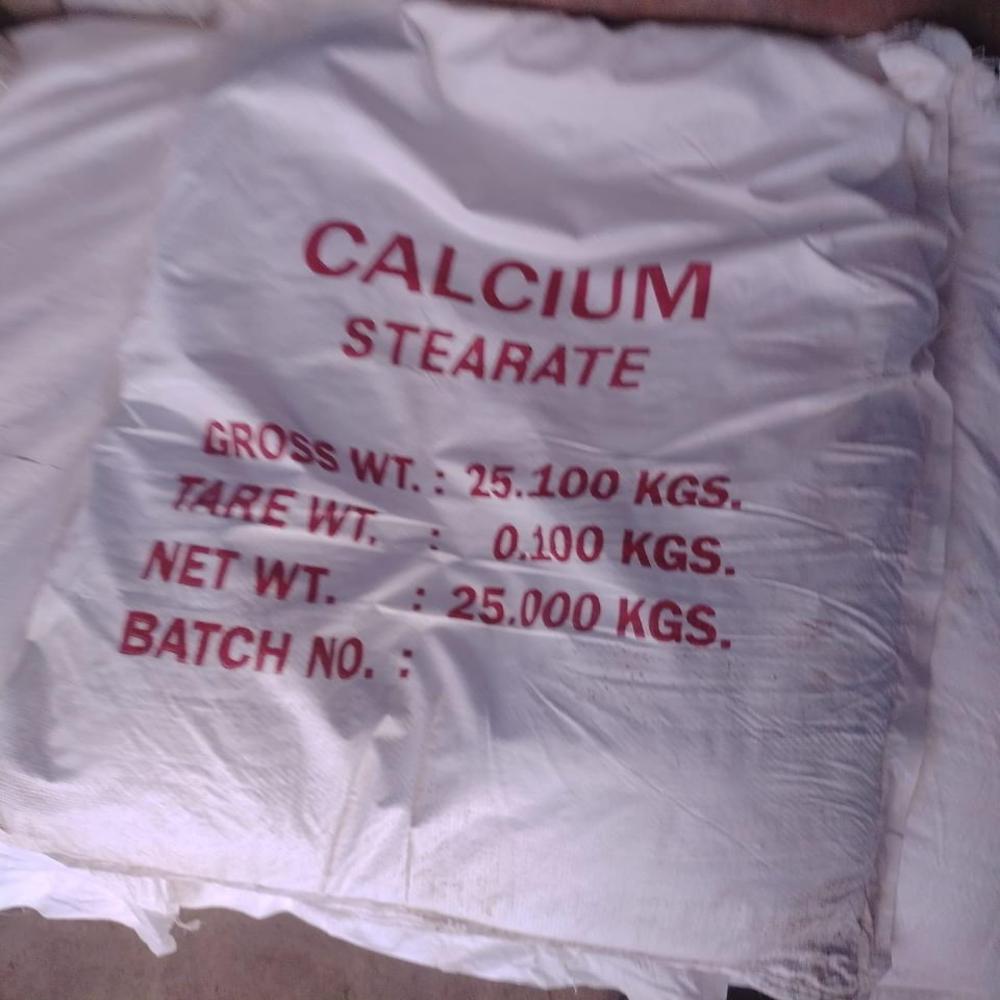

Calcium Stearate

75.0 INR/Kilograms

Product Details:

- Melting Point 146C

- Poisonous No

- Shape Powder

- Purity 98% Min

- Smell Odorless

- Molecular Weight 607.02 g/mol Grams (g)

- Solubility Insoluble in water; soluble in hot alcohol

- Click to View more

X

Calcium Stearate Price And Quantity

- 100 Kilograms

- 75.0 INR/Kilograms

Calcium Stearate Product Specifications

- Lubricant Stabilizer Waterproofing Agent

- Ca(C18H35O2)2

- GB/T 25744-2010

- Odorless

- 98% Min

- Insoluble in water; soluble in hot alcohol

- Solid

- 607.02 g/mol Grams (g)

- Powder

- 216-472-8

- No

- Other

- 1592-23-0

- 146C

- Powder

- 1.03 Gram per cubic centimeter(g/cm3)

- C36H70CaO4

- Calcium Salt

- Store in a cool dry place

- Calcium Stearate

- Industrial Grade

- Octadecanoic acid calcium salt

- Metallic Soap

- 7-9

- 29157090

Calcium Stearate Trade Information

- 2-3 Days

Product Description

Available in white powder form, calcium stearate acts as suitable mold releasing agent and lubricant in different industries. Being versatile by nature, it acts as an effective antioxidant and emulsifier in relevant field. This non toxic compound can resist moisture and water. It remains insoluble in water, but easily dilutes in acetone, warm ethanol and ethylene glycol. Low toxin content, odor free nature, non ionic composition and low vapor pressure are the key features of calcium stearate. Its standard has been verified as per its composition, shelf life, moisture content, possible toxin level and scope of application.

Key Features and Composition

Calcium Stearate boasts a molecular formula of C36H70CaO4 and is classified as a metallic soap. The primary material used is calcium salt, and it is presented in a powder form. Notably, it is an odorless substance with a density of 1.03 g/cm and a melting point of 146C, making it suitable for a range of industrial applications.

Industrial Applications and Standards

Meeting GB/T 25744-2010 standards and carrying an EINECS number of 216-472-8, Calcium Stearate is widely utilized as a lubricant, stabilizer, and waterproofing agent in manufacturing. Its stability and effectiveness make it ideal for the polymer, plastics, and construction sectors. Supplied as a solid powder, it is suitable for large-scale usage.

Safe Storage and Handling

To maintain its quality, Calcium Stearate should be stored in a cool, dry place, away from moisture and direct sunlight. Its odorless nature and insolubility in water contribute to safe handling and minimal environmental impact during transportation and storage.

FAQs of Calcium Stearate:

Q: How is Calcium Stearate typically utilized in industrial processes?

A: Calcium Stearate is employed as a lubricant, stabilizer, and waterproofing agent. It enhances the flow and processing of plastics and rubbers, prevents caking in powders, and improves the moisture resistance of finished products in industries such as plastics, construction, and paints.Q: What are the main benefits of using Calcium Stearate as a metallic soap?

A: As a metallic soap, Calcium Stearate offers excellent lubrication and thermal stability, helps reduce friction during manufacturing, and acts as an effective anti-caking and waterproofing agent. Its odorless and non-toxic properties also contribute to safer formulation and application.Q: When should Calcium Stearate be added to a production process?

A: It is usually incorporated during the initial mixing of raw materials to ensure even distribution of its stabilizing and lubricating effects. For optimal results, it should be blended at controlled temperatures due to its melting point of 146C.Q: Where is Calcium Stearate commonly stored to maintain its quality?

A: This compound should be kept in a cool, dry environment, away from direct sunlight and sources of moisture. Proper storage helps prevent degradation and maintains its efficacy as a powder.Q: What is the process for dissolving or using Calcium Stearate in formulations?

A: Although insoluble in water, Calcium Stearate can be dispersed in hot alcohol or incorporated as a solid into compounds like plastics and rubber. The powder form ensures ease of blending with other industrial materials without unwanted reactions.Q: Can Calcium Stearate be used in products that require high chemical purity?

A: Yes, with a purity of at least 98%, Calcium Stearate meets the standards for most industrial-grade applications. It is suitable where high purity and consistent performance are required.Q: What safety measures are necessary for handling Calcium Stearate during manufacturing?

A: While Calcium Stearate is generally regarded as safe and odorless, standard precautions include avoiding excessive inhalation of dust and wearing protective gear during bulk handling. Its chemically stable nature reduces the risk of hazardous reactions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS